Try to imagine laboratory animal science without IVC technology. It’s hard to picture, right? Or maybe you can imagine it clearly because you currently or previously worked in a laboratory without IVC systems. Either way, IVC technology has revolutionized observing and studying animals.

A few significant benefits of IVC technology are that it prevents cross-contamination, improves the air quality for animals, and decreases allergen exposure for lab personnel. But there’s a lot more to IVC technology than just those few things. Airflow mechanics, rack configurations, ventilation, and cage design all impact an experiment.

Ok, now that you have pictured the laboratory animal science field without IVC technology, try to envision your life without all of the advancements made by biomedical research. It’s not exactly an ideal scenario because laboratory animal science is responsible for virtually every disease treatment, medication, and vaccine available today. The great news is biomedical research is constantly evolving and improving to produce better research and exceptional treatments for people and their pets.

But none of these life-changing health solutions would be possible without the groundbreaking technology used in lab animal science over the years. Let’s not forget that every step towards technological advancement in lab animal science has been impactful.

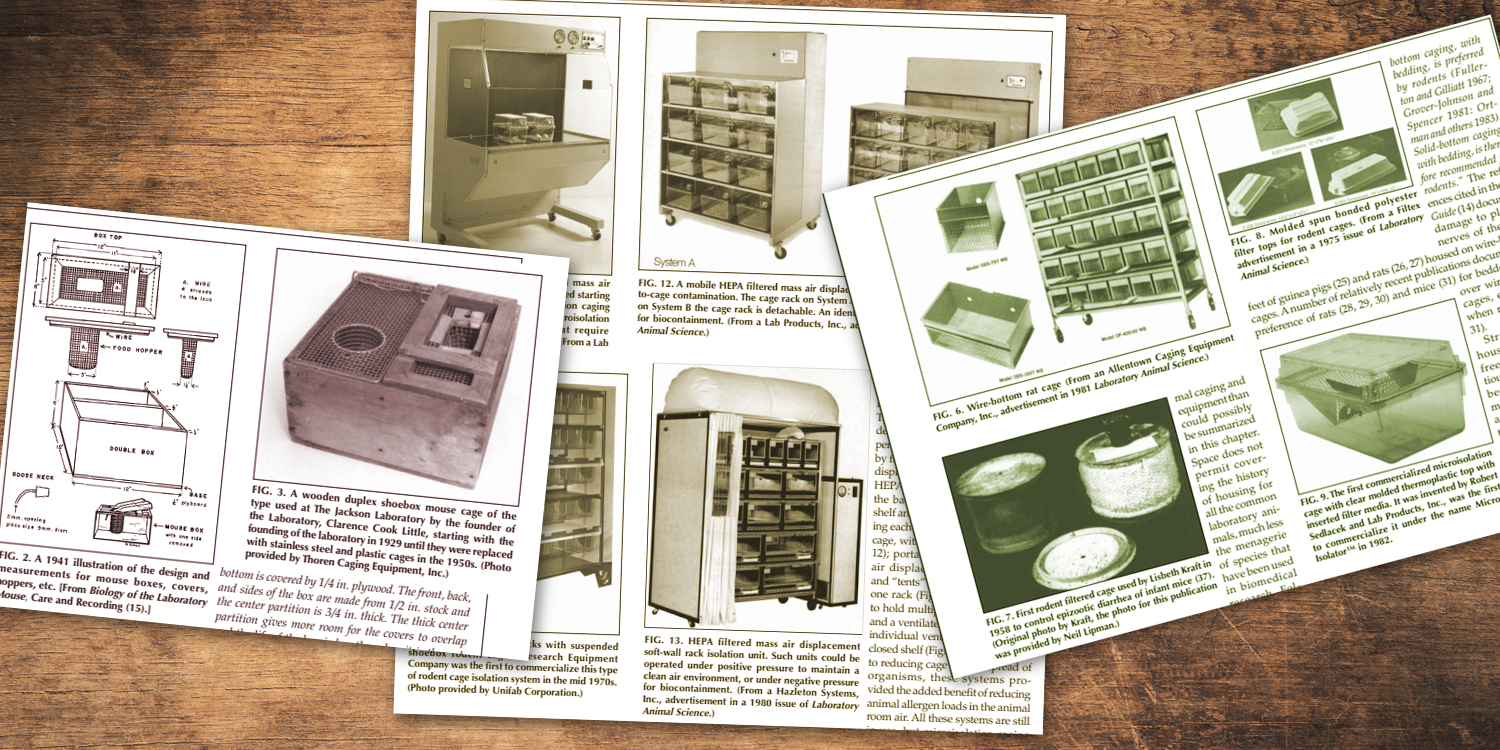

The Evolution of IVC Technology

IVC systems are the standard for housing animals across research facilities globally. So, where was the first IVC developed? Edwin P. Les of The Jackson Laboratory in Maine developed the first individually ventilated cage strategy in the mid-1960s.1 The objective of his invention was to control cage-to-cage disease transmission while improving the animals’ microenvironments. Another goal of individual ventilated cage systems was to save space. Increasing housing density allows researchers to conduct larger-scale, more reproducible studies.

Then Edwin P. Les joined forces with Thoren Caging systems to develop a better IVC system. Together, they created an IVC that “provided cage-level isolation by individually ventilating each cage with HEPA-filtered air supplied from a fan/filter module for each rack,” much like the IVC systems common today.1

By the 1980s, the demand for more biomedical research equipment rapidly increased. By the 1990s, IVC systems started to become widely accepted in the field. To date, ventilated caging systems provide an effective cage-level barrier while significantly improving the animals’ microenvironments.”1

Original Caging in Lab Animal Science

Wood Caging

Can you imagine some disadvantages that accompany a wooden IVC? Well, wood was the most popular material for animal cages in the early days of lab animal science in 1929.1 Wooden IVCs were chiefly used for housing rodent models.

One advantage of using wood housing for mice was that mice stayed warmer. Another benefit was that wood was inexpensive.1 However, unsurprisingly, wood housing was impossible to sanitize effectively. So, eventually, durable materials like glass, plastic, or metal became commonly used materials.1

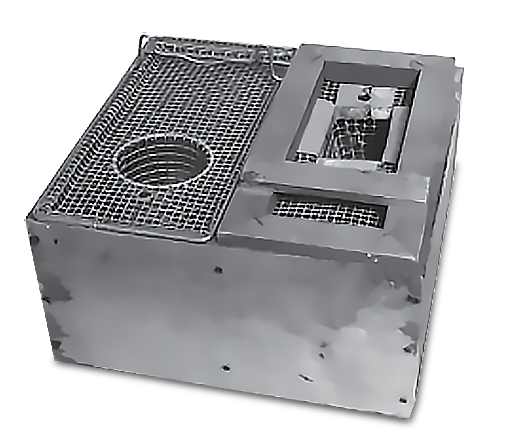

Metal Caging

Once metal caging became mainstream in lab animal science, galvanized steel was the most common metal.1 But galvanized steel had its limitations. Although it lasted longer than wood, frequent exposure to chemicals and hot water deteriorated the coating and caused rust. Also, galvanized metal releases zinc and other heavy metals into the animal’s environment.1

Eventually, stainless steel replaced galvanized metal. Stainless steel has proven to be the most cost-effective and durable. By the 1950s, stainless steel was the primary material used to manufacture mouse animal cages.

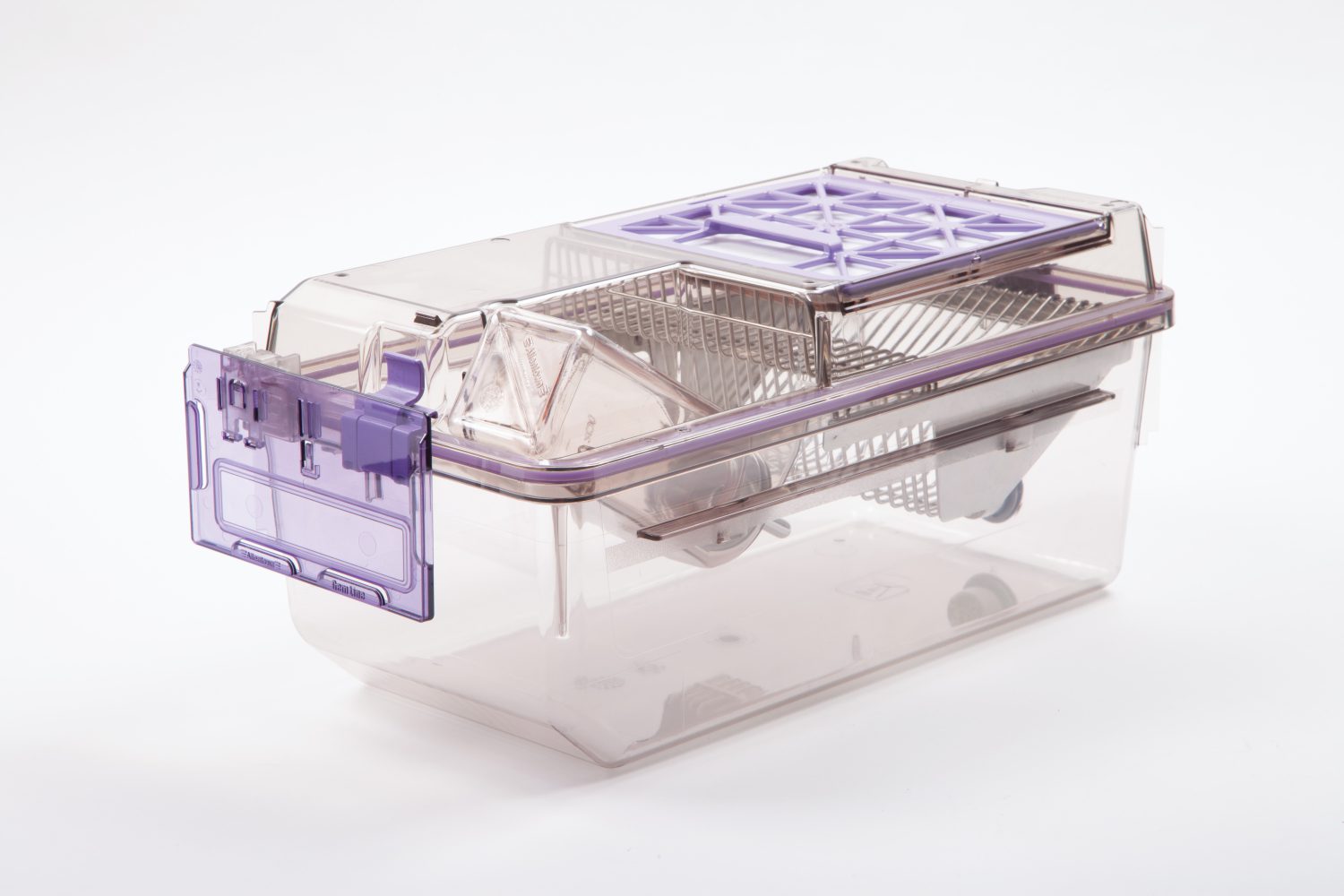

Plastic Caging

Then, in the 1960s and 1970s, molded plastic cages began replacing stainless steel cages.1 The primary reason plastic replaced stainless steel is that stainless steel impedes animal observation. So, although the stainless steel cages never wear out, most labs switched to plastic to improve animal observation.

Although plastic caging isn’t as durable as stainless steel, they are lightweight, which is beneficial for ergonomics.1 Also, plastic cages don’t become misshapen like stainless steel.1 Additionally, plastic enclosures have a lower coefficient of heat transfer, which is better for animal well-being.1

One early plastic, made in 1953, used for housing was polystyrene. But it wasn’t practical because it had low impact strength and was not autoclavable. Then in 1960, polypropylene was introduced because it was autoclavable. However, it was not see-through, which was a disadvantage.

Then, in 1962, polycarbonate plastic became the industry standard.1 Why? Because it’s a transparent, durable plastic with high impact strength and withstands autoclaving.1 But, repeated autoclaving caused the polycarbonate to become opaque, crack, and deteriorate.1

Polysulfone Plastic Revolutionizes IVC Technology

Plastic caging was a step up from metal caging, but it still had disadvantages. Polysulfone plastic, the current industry standard for laboratory animal caging, changed the game. Also, Polysulfone is a higher-temperature thermoplastic and is autoclavable. Additionally, it remains transparent, even after repeated washing with chemicals under high temperatures.

This high-grade plastic is fantastic because its integrity does not wither from repeated autoclaving but it shares the same benefits as other plastics. It is lightweight, which makes working with it safer and more ergonomic. Plus, it’s entirely see-through for easy, accurate observation. And it doesn’t become misshapen from washing or use.

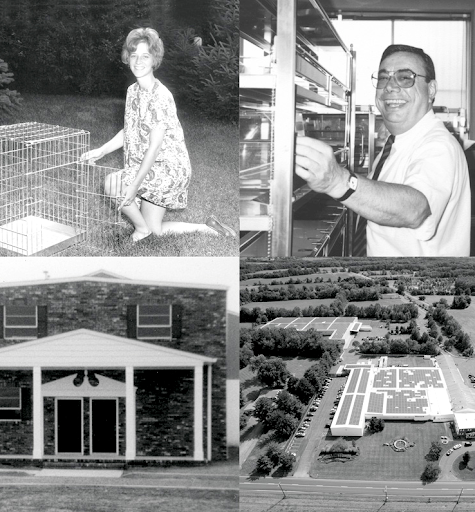

Allentown’s Influence on Husbandry and IVC Technology

Our story began in 1968 when our founder, Michael A. Coiro Sr., opened a small factory in Allentown, New Jersey, during a boom period for science industries. Initially trained in the artful technology of stainless steel, he soon experienced first-hand how important advances in biomedicine can be. All thanks to the innovative life-saving care that his wife and business partner, Dorothy, received at the Hospital of the University of Pennsylvania.

Michael exited that experience with a keen awareness of what was at stake and a passionate inspiration to contribute to the scientific mission. He poured care, dedication, and compassion into an operation that evolved into a state-of-the-art world-class organization and earned the trust and respect of biomedical research facilities around the globe.

References:

- 50 Years of Laboratory Animal Science. American Association for Laboratory Animal Science, 1999