In the landscape of medical device sterilization and decontamination, the search for the best sterilization methods remains critical. Enter the ClorDiSys proprietary chlorine dioxide gas, a formidable method poised to redefine the standards of medical device sterilization and decontamination. With a focus on maximizing efficiency and safety, this blog navigates through the impact of chlorine dioxide gas, offering insights tailored for medical device decision-makers seeking cutting-edge solutions.

Understanding Chlorine Dioxide Gas for Medical Device Sterilization

Chlorine dioxide (CD) gas is a powerful yellow-green gas that has been used as a sterilizing agent for medical devices and equipment for the last forty years, thanks to its sterile, penetrative properties.

During its sterilization process, CD gas penetrates the surfaces of medical devices and equipment. It works to attack the inner structures of harmful microorganisms like bacteria and viruses, including those resistant to antibiotics, ultimately preventing microorganisms from reproducing and causing infections. This process neutralizes the microorganisms, ensuring that the sterilized surfaces are free from harmful pathogens.

Overall, chlorine dioxide gas is favored for medical device sterilization due to its broad-spectrum effectiveness in eliminating pathogens, gentle process, minimal residue, and eco-friendliness.

Assessing Medical Device Sterilization Methods: Chlorine Dioxide Gas vs Ethylene Oxide

Currently, in the medical device decontamination space, ethylene oxide (EtO) is the most used gas for sterilizing medical devices. However, there’s a growing trend in the medical device sphere to transition away from it due to its carcinogenic nature, among other risks, such as its explosive properties (according to the EPA). As a result, chlorine dioxide gas is becoming a safer and more sustainable alternative for medical device decision-makers.

Other considerations come into play for decision-makers when finding the right solution for the sterilization method needs, so it’s important to understand how chlorine dioxide gas stacks up EtO, in a variety of ways.

Efficacy of CD Gas Compared to EtO

CD gas is an effective method for eliminating a variety of microorganisms. Ethylene oxide (EtO) also is highly effective in this area.

The Speed of Medical Device Sterilization

Chlorine dioxide gas usually requires shorter exposure times compared to ethylene oxide, resulting in faster sterilization cycles. Ethylene oxide is known for having longer cycle times due to its slower penetration rate.

Cost Comparison of CD Gas vs EtO

CD gas can be a more cost-efficient option compared to EtO with lower upfront costs and expenses with ethylene oxide requiring specialized equipment and safety measures, contributing to higher overall costs.

Medical Device Sterilization Safety: CD Gas vs EtO

CD Gas is non-carcinogenic, non-explosive, and does not cause corrosion or damage to delicate materials. Whereas, EtO is categorized as explosive, carcinogenic, and cannot safely sterilize batteries (according to the EPA).

Advantages of Chlorine Dioxide Gas for Medical Device Sterilization

Medical device sterilization is imperative for ensuring safety and eliminating harmful microorganisms from medical devices. By reducing the risk of infections associated with surgical procedures, diagnostic tests, and other medical interventions, CD gas has emerged as a reliable solution in this space, offering distinct advantages like:

Broad-Spectrum Efficacy: CD gas is highly effective against a wide range of microorganisms, including antibiotic-resistant bacteria, viruses, fungi, and spores. Its broad-spectrum efficacy ensures thorough sterilization, ultimately reducing the risk of potential infections associated with medical devices. *

Rapid Action: CIO2 acts quickly to neutralize harmful microorganisms, minimizing downtime for medical devices and equipment. *

Compatibility with Various Materials: CIO2 can come in contact with various materials commonly used in medical devices (i.e. plastics, metals, rubber, and electronics). It does not cause corrosion or damage to delicate materials, ensuring the durability of the sterilized devices. *

Environmental Friendliness: CIO2 is considered eco-friendly compared to other methods of sterilization. It does not produce harmful by-products or ozone-depleting substances, making it a sustainable choice for medical device sterilization. *

*Information on the efficacy of Chlorine Dioxide Gas is sourced from the Journal of the American Association for Laboratory Animal Science (JAALAS) and Applied Biosafety (APB), Journal of ABSA International.

Future Directions: Evolving Trends in Chlorine Dioxide Gas Decontamination

Advancements in CD gas sterilization tech are continually evolving, driven by the need for enhanced efficiency, and safety. Some potential future applications and innovations include enhanced delivery systems, novel validation methods, and environmental sustainability.

Enhanced Delivery Systems

Innovations in delivery systems, such as advanced vaporization techniques and automated sterilization chambers, aim to optimize the distribution and penetration of CD gas for more thorough and consistent sterilization of medical devices. This in turn could lead to a faster and more efficient sterilization process.

Novel Validation Methods

Advancements in validation methods, including the use of biological and chemical indicators, promote a more accurate and efficient assessment of sterilization efficacy. These methods provide healthcare facilities with confidence in the effectiveness of chlorine dioxide gas sterilization processes and may lead to streamlined validation procedures.

Environmental Sustainability

Future progress may focus on further enhancing the environmental sustainability of the chlorine dioxide gas sterilization process. This could include exploring alternative precursor chemicals and improving gas recovery and recycling systems while minimizing energy consumption during the sterilization process. These potential advancements aim to reduce the environmental footprint of chlorine dioxide gas sterilization.

In Conclusion: Chlorine Dioxide Gas Stands Out for Medical Device Sterilization

In closing, chlorine dioxide gas stands out as a reliable solution for sterilizing medical devices, offering numerous benefits such as broad-spectrum efficacy, rapid action, compatibility with various materials, and environmental friendliness.

As trends in this field continue to emerge in the medical space, CIO2 has the opportunity to overtake and solidify its place over other common sterilization methods like EtO. Continuing to capitalize on current successes with reduced cycle times, cost efficiency, and safety and sustainability, chlorine dioxide gas can become medical device decision-makers’ clear cutting-edge solution.

Therefore, considering the numerous advantages it offers, making the switch to chlorine dioxide gas technology for sterilization needs can revolutionize the sterilization process, ensuring optimal safety and efficacy for medical devices.

Learn More About ClorDiSys

ClorDiSys was established in 2001 by two former Johnson & Johnson visionaries, embarking on a journey focused initially on crafting Chlorine Dioxide gas equipment. However, guided by invaluable feedback from its clientele, ClorDiSys swiftly adapted, expanding its repertoire to include a range of complementary services and consumable products.

Today, ClorDiSys offerings span across vital sectors such as life sciences, healthcare, and medical devices. With an unwavering commitment to quality and innovation, they offer top-tier decontamination, disinfection, and sterilization solutions tailored to meet the rigorous demands of modern industries.

Headquartered in central New Jersey, ClorDiSys serves a global clientele. Their journey of over two decades has been marked by an unyielding dedication to their core values, fostering trust and reliability among their customers. For those seeking unparalleled service and cutting-edge solutions in the realm of disinfection and sterilization, ClorDiSys stands as the epitome of excellence.

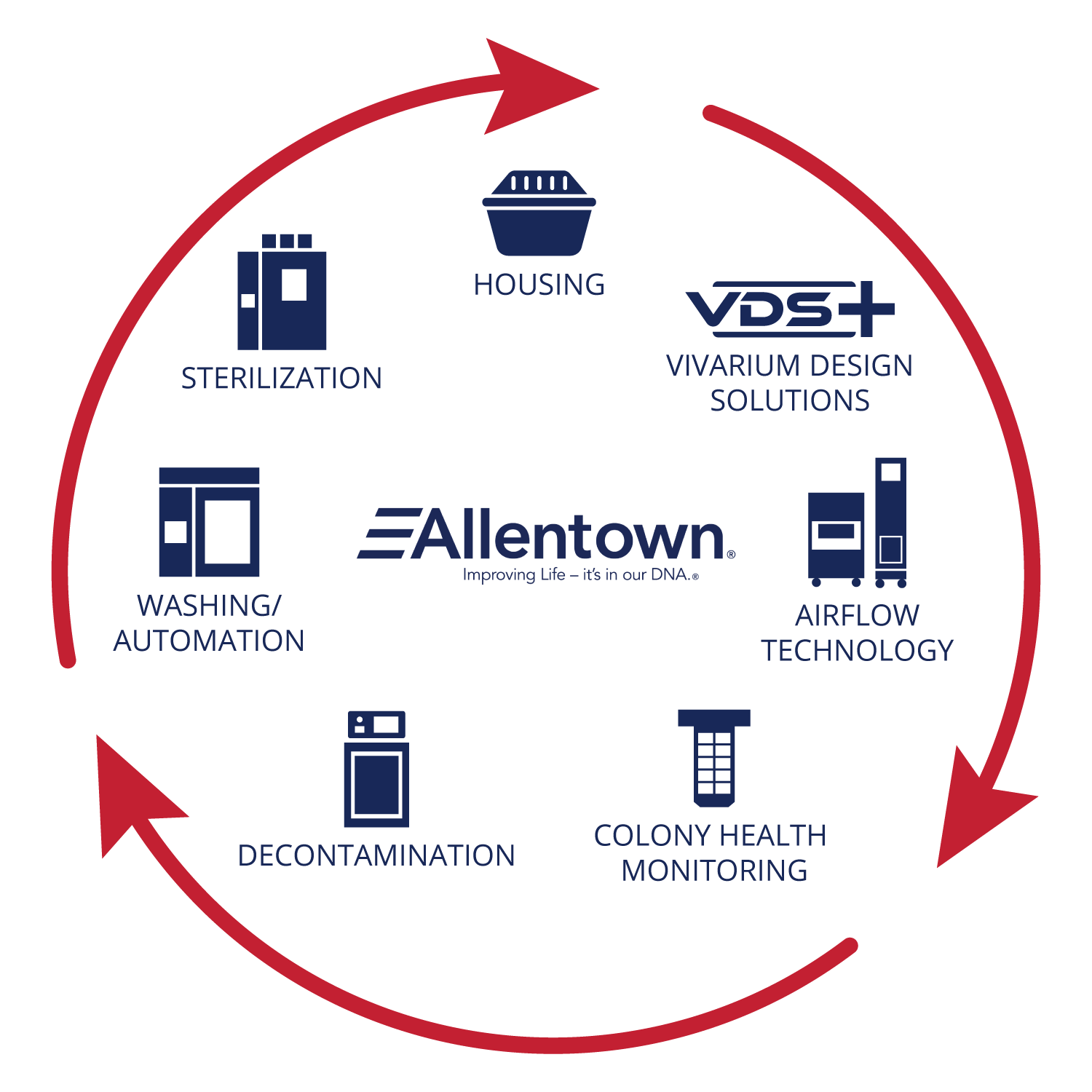

To learn more about chlorine dioxide gas sterilization and the solutions and services provided by ClorDiSys, an Allentown company, click the link.

Learn More ClorDiSys Proprietary Chlorine Dioxide Gas

The chlorine dioxide gas produced by ClorDiSys yields pure chlorine dioxide with a neutral pH of 7 when dissolved in water, making it gentle on materials, especially stainless steel. In fact, chlorine dioxide gas boasts a relatively low oxidation potential compared to other common decontaminating agents, as indicated in the table below. Despite the prevalent belief that chlorine dioxide gas shares the corrosive traits of its liquid counterpart, it’s crucial to differentiate between the two. While liquid chlorine dioxide derives its corrosive properties from the acidic components in its formulation, ClorDiSys chlorine dioxide gas should not be regarded in the same light.

Related Topic: Learn More About Sterilizer Maintenance

If you would like to learn about the importance of sterilization maintenance, read our recent blog story 3 Expert Reasons Why Sterilizer Maintenance & Service are Essential.